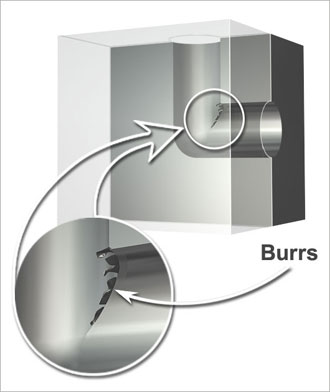

Deburring Cross-drilled Holes

ORBITOOL comes in two size configurations: one-hemisphere and two-hemisphere.

View Size Details | Download Brochure

Fintek is the UK agent for the J W Done patented Orbitool technology for the in-process deburring of cross-drilled holes.

Burrs always form at the intersections of crossed-drilled holes and the traditional off-line processes for dealing with them seriously interrupt modern manufacturing methods. Significant costs can mount through time delays caused by manual deburring queues or outsourcing deburring of the troublesome parts altogether.

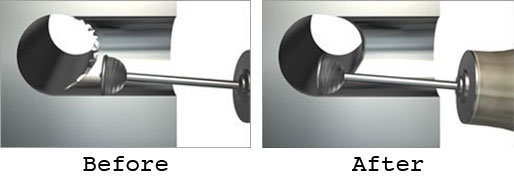

Before and after deburring with Orbitool

Benefits of Orbitool

- Simple set-up

- No need for special tooling

- Can be used in hand power tools

- Can also be CNC mounted

- Works on hard and soft materials

- Eliminates batches and queues

- Reduces deburring costs

- Increases productivity

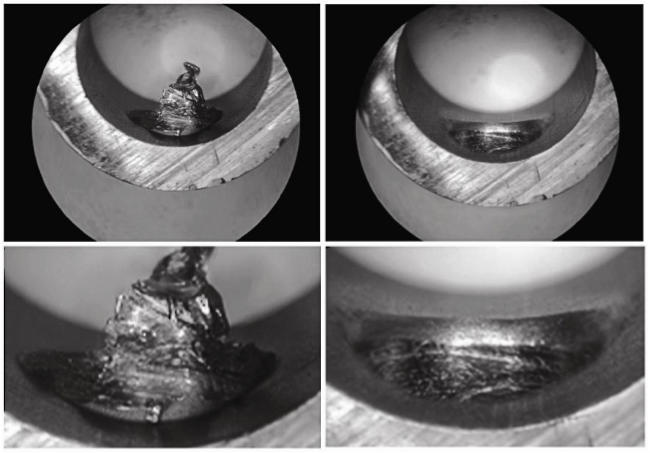

How Does Orbitool Work?

Orbitool is a shaped carbide cutter and polished steel disk mounted on a flexible tool steel shaft. The design makes it easy to mount in transfer machines, screw machines, CNC lathe turrets and tool magazines of milling machines.

Who Uses Orbitool?

Major motor manufacturers have used Orbitool to deburr camshaft drilled holes – where burrs breaking off were jamming the variable cam timing system. Pneumatic automation technology providers used Orbitool to prevent burrs breaking off into hydraulic manifold bore holes and undermining product integrity. Anyone who wants to ensure parts with drilled holes are not compromised by poor finishing.