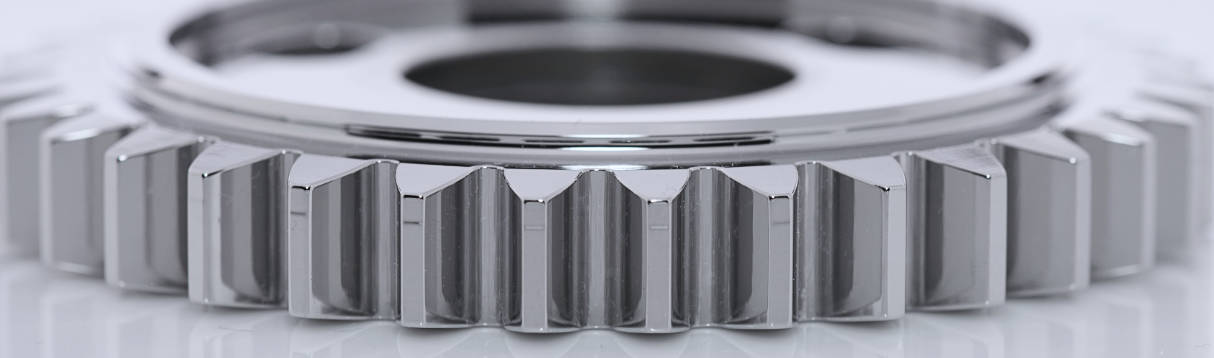

Subcontract Surface Finishing for Gears

Deburr, smooth and edge-round precision gears without increasing capital expenditure or labour

Call Fintek 01706 825819 or enquire here

Why subcontract gear and transmission component surface finishing to Fintek?

Precision gears and transmission parts are designed to run under extreme load for long durations. Deburring, smoothing and edge-rounding helps reduce:

- Friction and heat generation

- Fatigue, wear, vibration, and noise

- Lubrication breakdown and servicing intervals

- The risk of premature failure

- Zero capital expenditure, instant capacity: Access world class OTEC Präzisionsfinish disc, drag, stream and electro finishing – on demand

- Save time: we can easily remove milling lines on gears, often allowing you to reduce milling time by around 30%

- Repeatable results: Homogeneous smoothing to 0.05μm or less with minimal geometry change

- Large part finishing: Up to 900mm long, 900mm diameter and a weight of 200kg

- Fast turnarounds: whether engineered for the rapid development cycles of F1 or other purposes, we can help you meet your goals.

- Prove process before investing in a machine: For higher volumes a machine for inline production can be tested before purchasing

- Surface finished PVD coated parts: Fintek can improve component surfaces for better PVD coating application. And post coating for smoothing and to remove hard droplets

Fintek’s subcontract surface finishing service is trusted by high-performance industries where failure isn’t an option. Aerospace, Formula 1 and other autosports, automotive and marine, industrial machinery, energy and power and many more industries rely heavily on precision made gears. These can include spur gears, helical gears, screw gears, worm gears, rack and pinion gears and more.

In addition to gears, the typical transmission parts we post-process include steering rack pinions, clutch baskets, drive shafts, camshafts and more.

High-precision ground and case-hardened gears require extremely isotropic surfaces, including:

- Surface roughness Ra < 0.1 μm

- Easy removal of grinding lines

- Extremely low waviness

- Homogeneous rounding at edges and tooth tips

- Exceptionally low form deviation during processing

- Lower micro-pitting risk

Why Fintek uses OTEC Streamfinishing (not chemical vibratory)

Traditional chemically accelerated vibratory finishing can create serious production headaches:

- Higher process variation leading to more scrap risk

- Long cycle times (often 6–8 hours or more)

- Media may not reach tooth roots

- Chemical handling, disposal costs and hazards

OTEC Streamfinishing at Fintek is designed to overcome those constraints:

- Exceptionally low process variation (~1 μm)

- No hazardous chemical handling

- Closed-loop operation with no cost-intensive disposal

- Up to 4× faster finishing

- Super-fine media reaches small geometries / tooth roots

- One-step deburring, smoothing and edge-rounding

- Microscopic lubrication pockets help reduce lubricant film breakage

- Compatible before/after nitriding, PVD, DLC coatings

- Lowers scrap risk thanks to repeatable results

- Faster throughput and shorter lead times

- Improves durability and efficiency in engines/transmissions

- Reduces friction losses supporting CO2 reduction goals

- Improves EV range via drivetrain efficiency

“In testing there was a considerable five percent performance increase… it runs cooler too… confidence is critical.” — Kieran Sanga, Motorcycle Racer. Read the case study.

Steps to start your subcontract surface finishing with Fintek

With EN9100 and ISO9001 certifications you can rely on Fintek to handle your subcontract surface finishing of gear and transmission components. Take the next steps:

- Share drawings/spec & targets (Ra, radius, geometry)

- Book a finishing trial

- Contact us via the ‘Ask an Expert’ form

- Need subcontract services now! – call us

Call Fintek 01706 825819 or enquire here

|

Fintek Subcontract Surface Finishing Overview |

|

|

|

|

Want to purchase an OTEC stream finishing machine?

Prefer to bring finishing in-house? Fintek also supplies the complete range of advanced OTEC surface finishing machines and can advise on process set-up and commissioning to smooth production.