Orbitool - In-process Deburring of Cross-drilled Holes

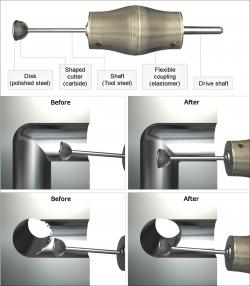

The problems associated with hand deburring cross-drilled and back-faced holes are eliminated by the Orbitool, available in the UK from Fintek. The Orbitool is the only in-process tool capable of removing burrs from the intersection of holes and is ideal for use on CNC machines, freeing the operator to concentrate on quality and high levels of throughput.

As many engineers appreciate, the cost of hand deburring can be greater than the cost of the manufactured part. Besides the increased time taken to hand deburr, it is near impossible to achieve consistent results – every part needing rigorous inspection – a process commonly open to human error. Orbitool removes these problems.

The Orbitool is used like other cutting tools on the lathe turret or tool magazine of a drilling machine, making it quick and easy to deploy. It shortens cycle times while achieving consistently high quality results and reduces the need to inspect every part. It also removes the need to batch process parts and eliminates process queues.

Engineers often ask: 'do you have a product which deburrs holes?'. The Fintek answer is the Orbitool. We are pleased to be able supply to the UK, a high quality product manufactured and patented by JW Done in the USA. This is a tool that really does make a difference to the bottom line for manufacturers.

The Orbitool is available with a range of options that allow it to be easily tailored to individual operations. Technical and UK pricing information is available from Fintek +44 (0)1706 825 819.

Click images to download