Boosting UK Productivity by Improving Cutting Tool Life and Performance

The latest drag and stream finishing machines from OTEC Präzisionsfinish are enabling us to provide tool users with a superior service that improves the performance and extends the life of cutting tools. Tool condition also directly affects the surface finish of a machined area and the probability of incurring more costs in further processing to meet the required end product quality.

From multiple axis CNC milling machines to simple drilling and lathing centres, quality and productivity of these machines is dependent on the sharpness, reliability and longevity of cutting tools. Replacing worn tools with new is costly and tempts some users to run longer with a less than optimum tool, putting quality and productivity at risk. The alternative of resetting the cutting machine to allow for tool defects is a risky and unnecessary.

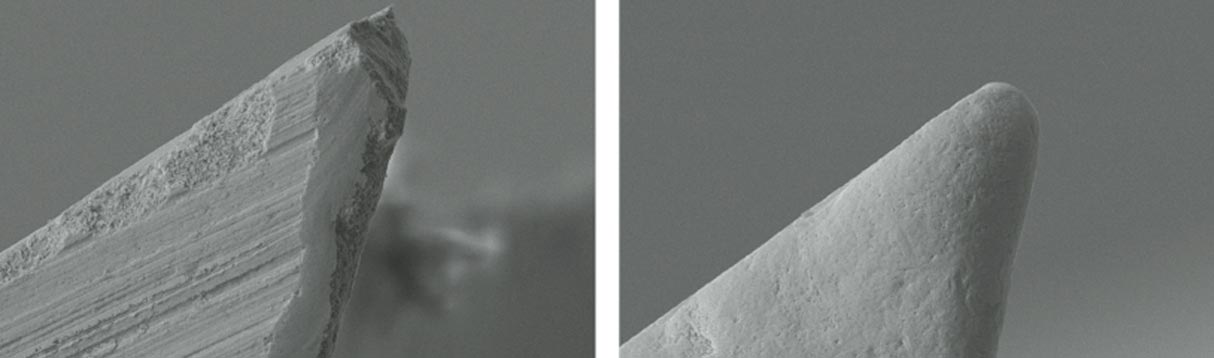

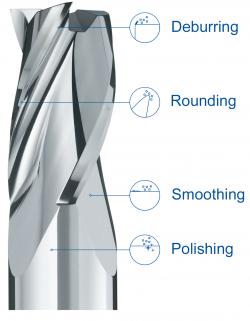

Managing director Jonathan Dean explains, “Worn tools – whether HSS, Carbide or coated can all be re-finished to the original manufacturer’s standard or sometimes even better. To achieve this takes more than re-grinding alone as this often leaves a sharp and brittle cutting edge which is easily chipped. Our surface finishing service not only grinds but also edge hones and smooths in one process. Edge honing puts a perfect radius on the cutting point, strengthening the edge to retain sharpness longer without chipping. We often more than triple tool life before it needs to be re-finished again.”

In the same cycle as precisely radiusing the edges of cutting tools to prevent chipping, the unevenness in the peaks on the surfaces in the chip flutes is removed. This reduces friction, wear and efficiently allows debris from the cutting point to be cleared – especially important for a difficult materials such as aluminium and composites. Again, in the same cycle, polishing takes surface smoothness even further. This precision process restores the original cutting geometries for the best tool performance.

For UK tool manufacturers, we can provide a full range of OTEC DF and SF machines for inline production. Manual or fully automated and robotised systems, ensure reliable, repeatable and cost effective cutting tool finishing. All are able to precisely edge radius, deburr, smooth and polish in a single cycle that can be measure in minutes and sometimes seconds.

To find out how to improve cutting tool life and performance, try the Fintek free trial part processing service: Tel 01706 82 5819.

Click images to download